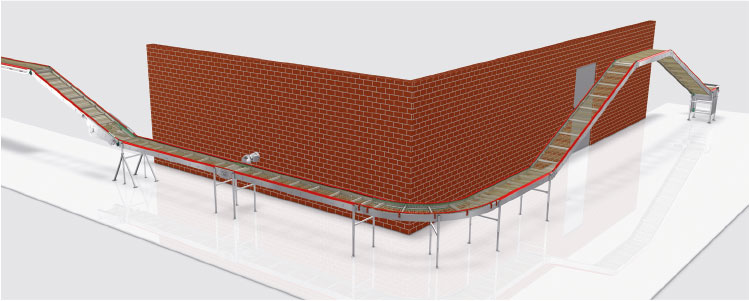

Egg Conveyor System – Reliable Egg Collection Equipment

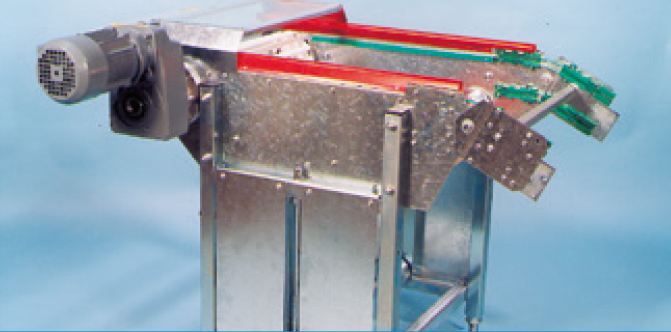

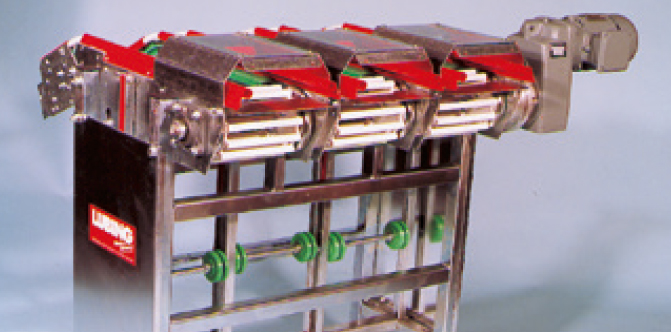

The egg conveyor system is an essential part of poultry farms of all sizes. As one of the key egg collection equipment, it ensures the safe and efficient transfer of eggs from the nest to the collection point, reducing breakage and improving overall productivity.

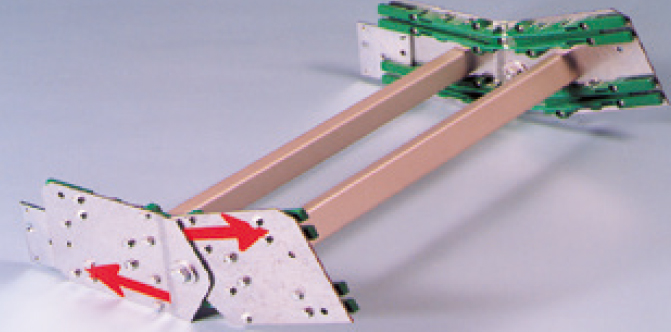

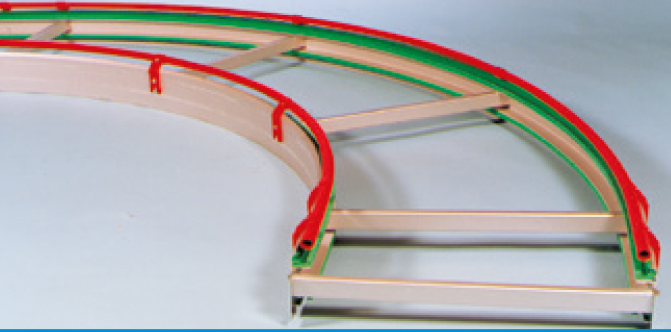

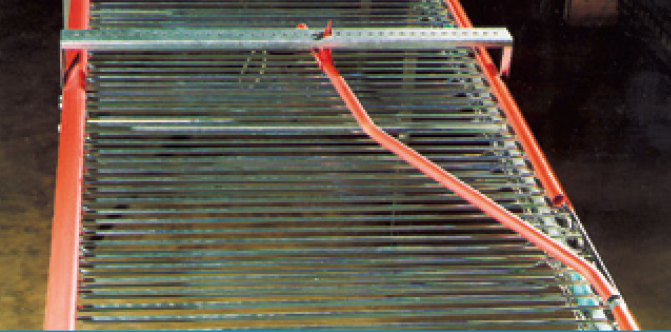

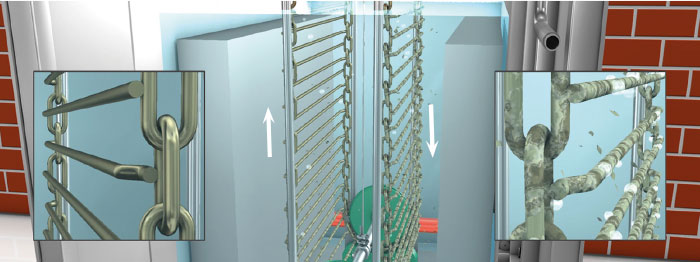

Variations in bird housing arrangement generally require custom-designed solutions. Our egg conveyor system has the ability to cope with any imaginable requirements; any necessary curves, heights and distances as followings:

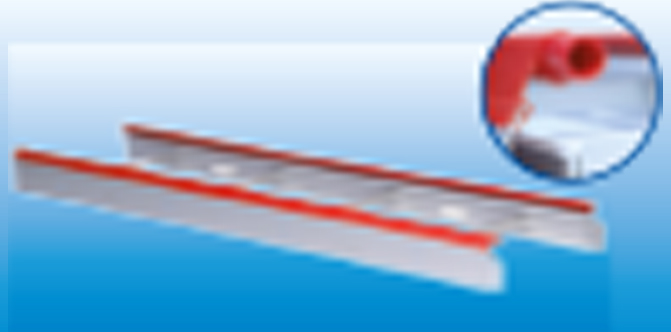

- Conveyor chain widths of between 200 and 750 mm.

- Capacities ranging from 15,000 to 65,000 eggs per hour.