Introduction: Automation as the New Standard

In the competitive landscape of modern agriculture, success in the Malaysian poultry industry is defined by efficiency, hygiene, and scale. For farm owners looking to minimise labour costs and maximise output, transitioning from manual handling to automated processes is no longer an option; it is a necessity.

At the heart of this automation shift lies the industrial conveyor system. Tong Seh Industries Supply Sdn Bhd (TSIS), a trusted farm equipment supplier in Malaysia, offers a range of industrial conveyor systems designed to meet the unique demands of the tropical climate and large-scale operations across Asia Pacific, including Malaysia.

This guide will explain the important role of industrial conveyor systems in modern poultry farming, detailing how they enhance productivity across layer, broiler, and breeder operations.

Why Automation is Essential for Modern Malaysian Poultry Farms

Farm operators today face increasing challenges such as rising utility costs, strict food safety regulations, and labour shortages. Industrial conveyor systems help overcome these challenges in several ways:

- Reduce Reliance on Labour

Conveyors handle high-volume tasks like feed distribution and egg collection, allowing staff to focus on bird welfare and maintenance. This dramatically reduces your operational headcount. - Ensure Consistent Hygiene

By minimising human contact with eggs, feed, and waste, automated systems significantly reduce the risk of contamination, supporting your compliance with local health regulations. - Optimise Feed Conversion

Automated feed conveyors deliver precise, consistent amounts of feed to every cage or pen, preventing wastage and optimising the growth rate of your birds.

The Role of Industrial Conveyor Systems in Poultry Operations

Industrial conveyor systems are specialised equipment engineered for poultry environments. They typically serve three main functions:

A. Feed Delivery Conveyors

Feed conveyors ensure that feed moves efficiently from storage silos to the feeding lines with minimal loss. Common systems include auger-based conveyors and flat chain mechanisms, both designed to prevent feed segregation and maintain consistent feed quality.

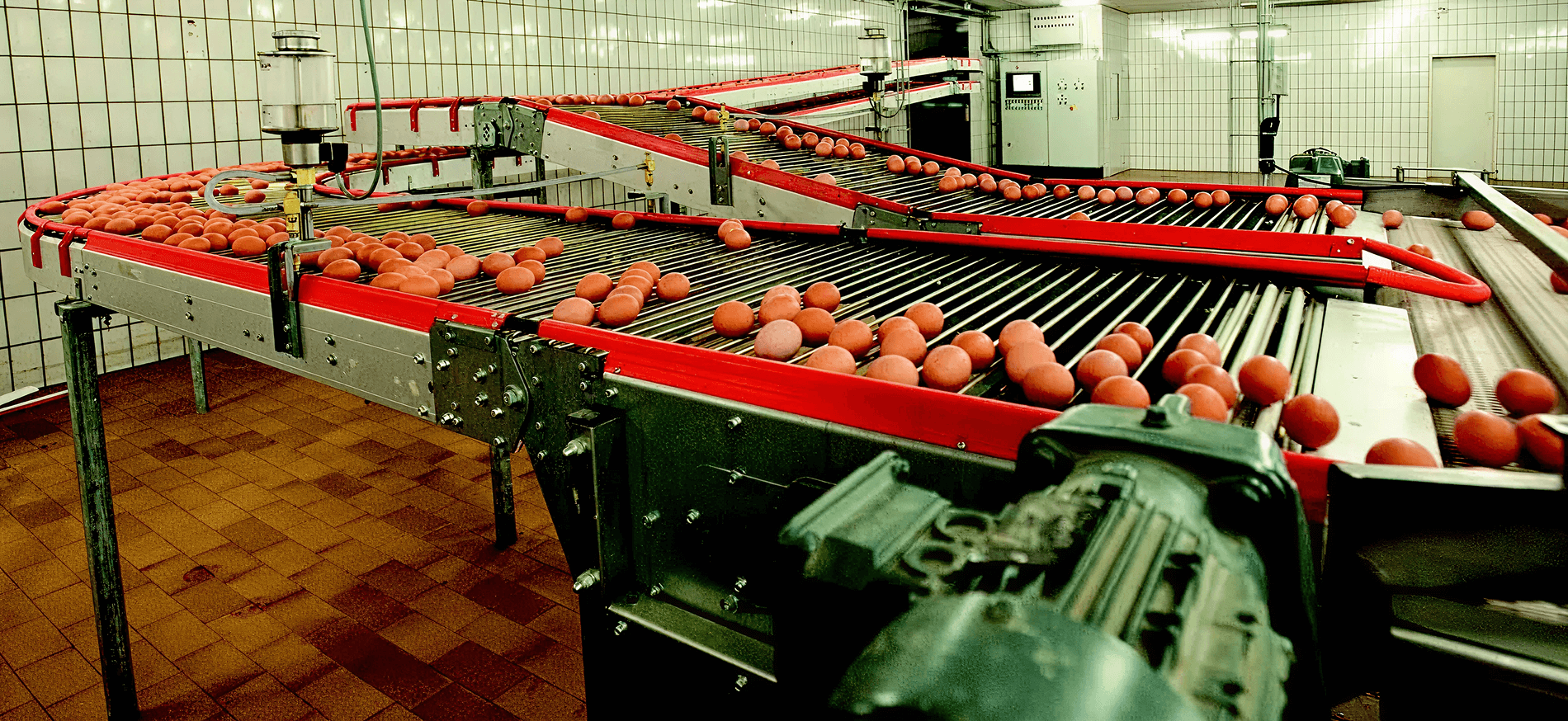

B. Egg Collection Conveyors

These conveyors are essential for layer and breeder farms. They are engineered to handle eggs gently and transfer them smoothly from cages to a central collection area. High-quality belts or rod conveyors help minimise cracks and maintain shell cleanliness.

C. Manure Removal Conveyors

Manure removal conveyors, often used in Manure Belt Battery (MBB) systems, are positioned beneath cages to collect and remove waste efficiently. Quick removal of manure improves ventilation, reduces ammonia levels, and promotes healthier living conditions within the poultry house.

Key Conveyor Systems for Different Poultry Segments

The type of conveyor you need depends heavily on your farm segment:

Layer and Breeder Farms (Egg Production)

Focus: Gentle egg handling with consistent movement

System Example: Egg Elevator and Egg Conveyor

Requirement: Durable, low-vibration belts designed to protect egg quality

Broiler Farms (Meat Production)

Broiler houses rely heavily on efficient feed delivery to maintain growth rates.

System Example: Flex Auger and feed transfer conveyors

Requirement: High-capacity and continuous operation to support large flocks

Comprehensive Waste Management

System Example: Manure Belt Battery (MBB)

Requirement: Corrosion-resistant belts suitable for humid Malaysian environments and easy cleaning

Choosing the Right Industrial Conveyor System: 5 Factors to Consider

Before investing in a new system, Malaysian farm owners should evaluate these critical factors to ensure longevity and a strong return on investment:

| Factor | Description | Why it Matters in Malaysia |

|---|---|---|

| Material & Durability | Opt for stainless steel or galvanised, non-corrosive materials for all moving parts. | High heat and humidity accelerate corrosion. Poor materials will lead to frequent breakdowns and high maintenance costs. |

| Climate Resilience | Systems should be designed to handle ambient temperatures and high moisture without warping. | Equipment must be specifically rated for tropical climates, ensuring consistent performance year-round. |

| Energy Efficiency | Motors and drives should be optimised for low power consumption. | Electricity costs are a major operational expenditure. Energy-efficient conveyors save you thousands over the system’s lifetime. |

| Integration Capability | The new conveyor must connect seamlessly with your existing infrastructure, such as feeding troughs, cages, and waste pits. | Poor integration disrupts workflow and increases costs. |

| Local Support & Service | The supplier should be a local manufacturer with dedicated service teams and spare parts inventory. | Downtime during an egg collection or feeding cycle can be devastating. TSIS ensures rapid deployment of experienced engineers for minimal disruption. |

Beyond Conveyors: Tong Seh’s Integrated Solutions

TSIS provides complete solutions that complement its conveyor systems, including:

- Poultry equipment such as layer cages, breeder systems, and climate control units

- Livestock equipment for various farming segments

- Biogas equipment that converts collected manure into renewable energy

These integrated systems help ensure efficiency, sustainability, and long-term operational resilience.

Ready to Automate Your Farm?

Implementing an automated industrial conveyor system is one of the most effective ways to secure the long-term profitability and sustainability of your Malaysian poultry farm.

If you are looking to upgrade your operations, improve hygiene standards, and future-proof your business, contact our team of experienced engineers today. We provide customised consultations to design a system that precisely fits your scale, segment, and budget.

Get in touch with Tong Seh Industries Supply Sdn Bhd now to request a detailed consultation!

FAQ About Industrial Conveyor Systems for Poultry Farms

What is an industrial conveyor for poultry farms?

An industrial conveyor system for poultry farms is a mechanical system designed to transport eggs, feed, or waste efficiently. It reduces manual labour, improves workflow, and ensures consistent output.

How does an automatic egg conveyor improve efficiency?

By moving eggs directly from cages to collection points, an automatic egg conveyor reduces labour, minimises breakage, and ensures eggs are collected in a central location for grading or packing.

Can the Egg Elevator handle high-volume production?

Yes. Tong Seh conveyors are designed for commercial layer farms, capable of handling large volumes efficiently.

Can the speed of the conveyor be adjusted for different farm processes?

Yes. Many systems, including egg conveyors and feed augers, come with speed controllers for flexible operation.

Are Tong Seh conveyors compatible with layer cages?

Yes. Systems such as the TSIS Egg Elevator integrate seamlessly with commercial layer cage setups.

How long do industrial conveyor systems usually last, and what maintenance is required?

Industrial conveyor systems typically last 10 to 20 years, depending on usage and maintenance. Regular maintenance includes cleaning, lubrication, periodic inspections, belt tension adjustments, and replacing worn parts to ensure long-term performance.

Conclusion: Building Smarter, More Efficient Farms

Industrial conveyor systems are central to modern poultry and livestock automation. Whether used for egg collection, feed distribution, or manure removal, they help farmers increase efficiency, reduce labour, improve hygiene, and protect product quality.

Tong Seh Industries Supply offers tailored, specialised conveying solutions designed for agricultural environments. Contact our team for customised recommendations and professional support.

Disclaimer:

The information provided in this article is for general informational purposes only. Readers are encouraged to consult with a qualified professional or contact Tong Seh for advice and solutions tailored to their specific needs. While we strive to provide accurate and up-to-date information, we cannot guarantee that it is entirely error-free. Tong Seh Industries Supply Sdn Bhd (TSIS) assumes no responsibility for any errors or omissions.